Manufacturing Recycling & Reuse Solutions

Waste Optima’s industrial solutions overview connects manufacturing byproducts with recycling and reuse outlets. From organics and paper to plastics, chemicals, heavy industrial byproducts, and surplus inventory, we design Sustainable³ programs that turn production waste into resources instead of landfill costs.

Solutions Index

-

Inventory Liquidation

-

Heavy Industrial

-

-

Bulk Plastics

-

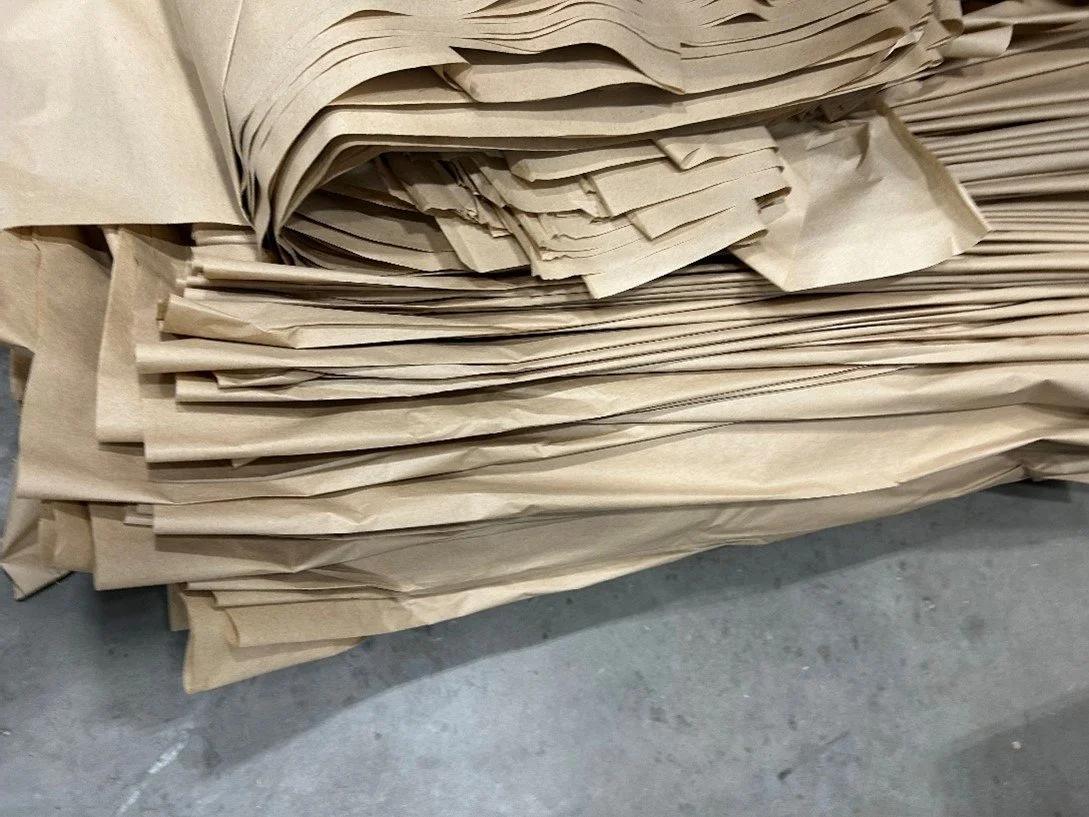

Cardboard & Fiber

-

Chemicals & Sludges

Industrial Recycling & Reuse for Manufacturers

Our solutions for industrial production byproducts focus on two paths: recycling the material or matching it with another enterprise that can use it as input in their own process. Whether your facility generates excess inventory, secondary-quality product, mineral fines, packaging waste, or spent chemicals, we work to uncover value in materials traditionally seen as waste.

Waste Optima can collect, recycle, and redirect a wide range of manufacturing byproducts—such as wire and cable reels, spools, and other specialty materials—through our nationwide industrial recycling and reuse network. We view each byproduct as a potential resource and approach every challenge with creativity, technical insight, and a commitment to long-term sustainability.

Guided by the Sustainable³ Framework

Our process is guided by the Sustainable³ framework, which ensures every solution is economical, operationally practical, and environmentally sound. If a material can be reused, we work to find a way—designing recycling and reuse programs that protect employee safety, maintain compliance, and reliably divert waste from landfill.

What is industrial recycling?

FAQs

Q1. What types of materials does Waste Optima handle?

We work with a wide range of industrial byproducts, including organics and food waste, paper and cardboard, plastics, chemical byproducts and sludges, heavy industrial materials like slag and dusts, and surplus or secondary-quality inventory from manufacturers and warehouses.

Q2. How do I know which solutions page to start with?

Start by matching your primary waste streams to the closest category: Organics, Paper, Plastics, Chemicals & Sludges, Heavy Industrial, or Surplus Inventory. If you’re not sure, we can review a short description and photos and point you to the right solution path.

Q3. How does your process work across different materials?

We typically begin with a high-level waste assessment, then evaluate outlets, logistics, and economics for each byproduct category. From there, we design site-specific or multi-site programs, coordinate transportation, and provide diversion reporting so you can track results across all streams.

Q4. Which industries do you serve?

Our solutions are built for manufacturers, warehouses, and industrial facilities across the U.S.—including heavy industry, food and beverage, packaging, chemicals, and logistics operations that generate recurring byproducts and surplus materials.

Q5. Do you support multi-site or nationwide programs?

Yes. We work with single facilities and multi-site networks, using a national recycler and reuser network to design regional solutions, coordinate pickups, and consolidate reporting across locations.

Q6. How do I get started?

You can start by contacting us with a brief overview of your major waste streams and locations. We’ll recommend which solution categories fit best and outline next steps for data collection, sampling (if needed), logistics, and program launch.

Last updated: 2025-12-10

Get in touch

Ready to benefit from advanced industrial recycling solutions? Connect with Waste Optima today by filling out our contact form or reaching out to our team. We’ll help you turn byproducts, surplus inventory, and other industrial wastes into practical recycling and reuse programs that support your economic, operational, and environmental goals.